India has always been a land of innovation, and the recent news about an Indian startup successfully 3D printing a rocket engine in just 72 hours adds another feather to its cap. This breakthrough not only underscores India’s growing prowess in cutting-edge technology but also highlights the transformative potential of 3D printing in the aerospace industry. The engine, made from high-performance nickel and chromium alloy, represents a significant leap in manufacturing capabilities and promises to reshape how we think about building rocket components.

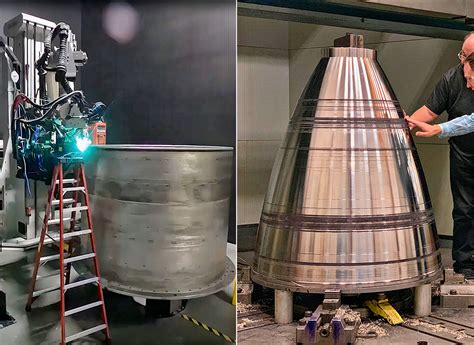

The world of rocket engineering is traditionally dominated by painstakingly manual processes, where constructing a single engine can take several months. By employing 3D printing, this startup has managed to reduce this timeline to merely three days—a feat that many in the industry are calling revolutionary. The Indian startup utilized a highly advanced metal 3D printer, provided by the German company EOS, which allowed them to fabricate the entire structure seamlessly. According to reports, the machine even generates an automatic report detailing any deviations in the printing process. This could ostensibly remove the need for extensive post-fabrication qualifications—a claim that has its skeptics but spells a brighter, faster future for aerospace manufacturing.

Not everyone is sold on the idea. Some industry experts argue that while 3D printing speeds up the manufacturing process, it cannot completely replace traditional methods of quality assurance (QA). In any engineering feat, especially one that involves launching objects into space, the need for rigorous post-manufacturing tests remains critical. Historically, technologies in the aerospace industry are subject to the highest levels of scrutiny. From X-ray scans to destructive testing involving sawing parts to inspect for internal faults, the checks are rigorous and uncompromising. This startup’s assertion that their machine omits the need for such validations has raised eyebrows, especially among seasoned professionals.

The advancement does, however, suggest a future where 3D printing will play a big role in technological and industrial revolutions across various sectors. The ability to produce complex geometries—sometimes with intricate internal channels for cooling or fuel delivery—makes 3D printing particularly advantageous for rocket engines. Traditional manufacturing methods struggle to achieve the same efficiency and complexity. This makes the technology extremely valuable, notwithstanding the ongoing debates about QA and testing. For example, SpaceX has long used 3D printing for its Draco and SuperDraco engines, demonstrating that additive manufacturing can indeed meet the stringent requirements of space missions when coupled with robust testing protocols.

There’s also a larger geopolitical context to consider. India’s burgeoning prowess in high-tech industries could shift the balance of technological power globally. As noted by some analysts, this achievement has significant military and strategic implications. A rocket engine completed in 72 hours could leverage India’s ballistic missile strategies, which are vital for national defense, especially given the regional tensions. Moreover, it signals India’s imminent rise as a formidable player in the space race, joining the ranks of the U.S., China, and Russia with its groundbreaking innovations.

The economic and cultural effects of such an accomplishment cannot be understated. For many, this is a testament to India’s potential and a clarion call to the Indian diaspora to further invest in the country’s tech landscape. Notably, the venture capital firm that funded this Indian startup was led by a prominent Indian-American professor, highlighting the increasing juncture of U.S. and Indian tech ecosystems. With a strong sense of pride and shared identity, there’s a growing movement of reverse brain and capital drain, bringing expertise and investment back home.

Critically, this development is part of a larger trend where the distinction between traditional and additive manufacturing is becoming increasingly blurred. The rapid iteration capabilities of 3D printing can democratize access to advanced materials and manufacturing techniques, potentially leveling the playing field for smaller firms and new entrants. This democratization could ignite a new wave of innovation, allowing more diverse and widespread contributions to global technological advancements.

In conclusion, while skepticism surrounding the Indian startup’s claims persists, the broader implications of their achievement cannot be ignored. The combination of 3D printing and aerospace engineering has the potential to shift paradigms, ushering in an era where speed and efficiency are drastically improved. With proper balance and rigorous testing, this breakthrough could catalyze a new wave of innovation in the aerospace sector, enabling faster, more cost-effective space missions. As we look to the future, it’s vital to celebrate and scrutinize such achievements equally, paving the way for truly transformative technological advancements.

Leave a Reply